Introduction and Overview¶

Note

consider the usage of logging when executing long running commands:

import logging

logging.basicConfig(level=logging.INFO,

format='%(asctime)s %(message)s')

Run FEMAG with FSL¶

Run a single calculation (single process):

workdir = os.path.join(os.path.expanduser('~'), 'femag')

femag = femagtools.Femag(workdir)

femag.run('femag.fsl')

Run several calculations in parallel (multi processes):

engine = femagtools.multiproc.Engine()

job = engine.create_job(workdir)

for fsl in ('femag-1.fsl', 'femag-2.fsl', 'femag-3.fsl'):

task = job.add_task()

task.add_file(fsl)

numtasks = engine.submit()

status = engine.join()

Read BCH/BATCH File¶

Read a BCH file and print the machine torque:

bch = femagtools.read_bchfile('TEST_002.BCH')

print(bch.machine['torque'])

Convert a BCH file to XML by command line:

python -m femagtools.bchxml TEST_002.BCH

This command creates the file TEST_002.xml

Read I7/ISA7 File¶

Read an ISA7/I7 File (filename extension is optional):

>>> isa = isa7.read('foo')

Print Node coordinates:

>>> n = isa.nodes[0]

>>> print(n.x)

(0.03380740433931351)

>>> print(n.y)

(0.009058667346835136)

>>> print(n.xy)

(0.03380740433931351, 0.009058667346835136)

Get an Element by key:

>>> el = isa.elements[0]

Inspect Element properties:

>>> el.mag

(0.8485281467437744, 0.8485281467437744)

>>> el.reluc

(0.9523810148239136, 0.9523810148239136)

Get Node coordinates of Element:

>>> el_coords = [v.xy for v in el.vertices]

>>> print(el_coords)

[(0.036389999091625214, 1.142020034095026e-09),

(0.03499503806233406, 0.0005893968627788126),

(0.03500000014901161, 0.0)]

Get a SuperElement by Element:

>>> spel = isa.superelements[el.se_key]

>>> el in spel.elements

True

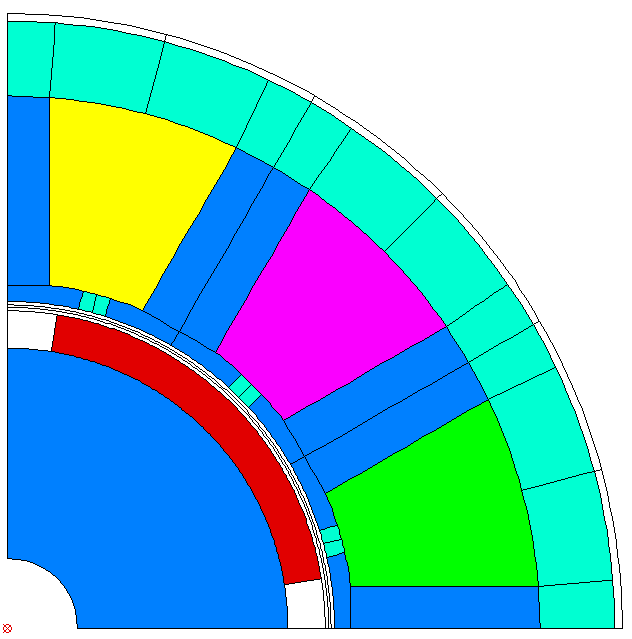

Plot SuperElements:

from femagtools import isa7

import matplotlib.pyplot as plt

from femagtools import plot

isa = isa7.read("PM_130_L4.ISA7")

fig = plt.figure()

ax = fig.add_subplot(111, aspect='equal')

plot.spel(isa)

plt.show()

Create FSL and/or invoke FEMAG with Model Parameters¶

Create a FE model from the templates stator1 and magnetSector:

machine = dict(

name = "PM 130 L4",

lfe = 0.1,

poles = 4,

outer_diam = 0.13,

bore_diam = 0.07,

inner_diam = 0.015,

airgap = 0.001,

stator = dict(

num_slots = 12,

mcvkey_yoke = "dummy",

rlength = 1.0,

stator1 = dict(

slot_rf1 = 0.057,

tip_rh1 = 0.037,

tip_rh2 = 0.037,

tooth_width = 0.009,

slot_width = 0.003)

),

magnet = dict(

mcvkey_shaft = "dummy",

mcvkey_yoke = "dummy",

magnetSector = dict (

magn_num = 1,

magn_width_pct = 0.8,

magn_height = 0.004,

magn_shape = 0.0,

bridge_height = 0.0,

magn_type = 1,

condshaft_r = 0.02,

magn_ori = 2,

magn_rfe = 0.0,

bridge_width = 0.0,

magn_len = 1.0 )

),

windings = dict(

num_phases = 3,

num_wires = 100,

coil_span = 3.0,

num_layers = 1)

)

fsl = femagtools.create_fsl(model)

with open('femag.fsl', 'w') as f:

f.write('\n'.join(fsl))

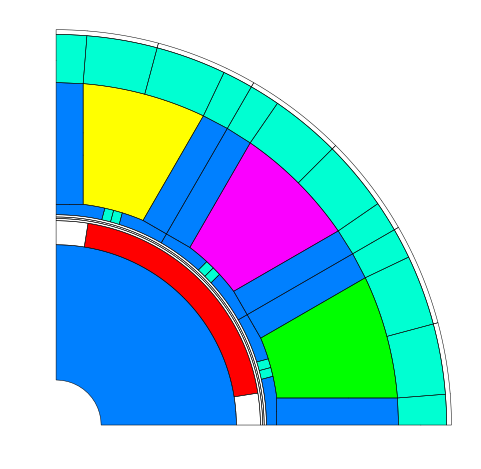

After opening this file in FEMAG the shown geometry is created:

The same machine and operating parameters can be used to run FEMAG directly:

femag = femagtools.Femag(workdir)

operatingConditions = dict(

calculationMode="pm_sym_fast",

current=50.0,

angl_i_up=0.0,

speed=50.0,

wind_temp=60.0,

magn_temp=60.0)

r = femag(machine,

operatingConditions)

print('Torque [Nm] = {}'.format(r.machine['torque']))

Evaluate PM/Reluctance machine characteristics¶

Definition of the PM or Reluctance machine with Ld,Lq parameters:

p = 4

r1 = 0.0806

ls = 0.0

ld = [1.4522728e-3, 1.4522728e-3]

lq = [3.2154e-3, 3.8278836e-3]

psim = [0.11171972, 0.11171972]

i1 = [80.0]

beta = [0.0, -41.1]

pm = femagtools.machine.PmRelMachineLdq(3, p,

psim,

ld,

lq,

r1,

beta,

i1)

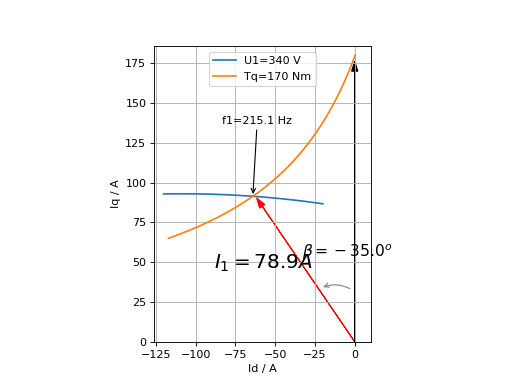

Calculation of minimal current and frequency at given torque and max voltage:

tq = 170.0

u1 = 340.0

iqx, idx = pm.iqd_torque(tq)

w1 = pm.w1_u(u1, idx, iqx)

i1 = np.linalg.norm(np.array((iqx, idx)))

(Source code, png, hires.png, pdf)

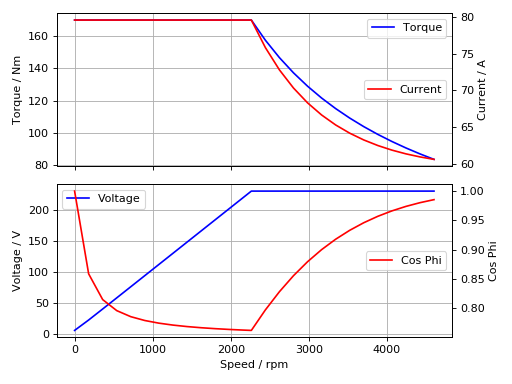

Speed-Torque characteristics with max power:

def torque(T, pmax, wm):

"""shaft torque as a function of rotor angular speed"""

if wm <= pmax / T:

return T

return pmax / wm

pmax = 60e3

n = np.linspace(0, 75, 20)

T = [torque(Tmax, pmax, 2*np.pi*nx) for nx in n]

r = pm.characteristics(T, n, u1)

(Source code, png, hires.png, pdf)

Execute Parameter Variations¶

Example: calculate torque, torque ripple and iron losses at beta=-50°,-25°,0°:

parvar = {

"objective_vars": [

{"name": "dqPar.torque[-1]"},

{"name": "torque[-1].ripple"},

{"name": "machine.plfe[-1]"}],

"population_size": 3,

"decision_vars": [

{"steps": 3,

"bounds": [-50, 0],

"name": "angl_i_up"}

}

operatingConditions = dict(

angl_i_up=0.0,

calculationMode="pm_sym_fast",

wind_temp=60.0,

magn_temp=60.0,

current=50.0,

speed=50.0)

numcores = 3

engine = femagtools.multiproc.Engine(numcores)

mcvDir = os.path.join(

os.path.expanduser('~'), 'mcv')

g = femagtools.grid.Grid(workdir,

magnetizingCurves=mcvDir)

results = g(parvar, pmMachine,

operatingConditions, engine)

The variable results is a dict with the keys x and f holding the (n x m) arrays of the decision and the objective variables.

Make a Multi-Objective Optimization¶

Example: minimize ripple and losses and maximize torque (note the sign parameter) by varying magnet width and height

optdef = {

"objective_vars": [

{"name": "dqPar.torque[-1]", "desc": "Torque / Nm", "sign": -1},

{"name": "torque[0].ripple", "desc": "Torque Ripple / Nm"},

{"name": "machine.plfe[-1]", "desc": "Iron Loss / W" }

],

"population_size": 24,

"decision_vars": [

{"name": "magnet.magnetSector.magn_width_pct",

"desc": "Magn width",

"bounds": [0.75, 0.85]},

{"name": "magnet.magnetSector.magn_height",

"desc": "Magn height",

"bounds": [3e-3, 5e-3]}

]

}

engine = femagtools.condor.Engine()

opt = femagtools.opt.Optimizer(workdir,

magnetizingCurve, magnetMat)

num_generations = 3

results = opt.optimize(num_generations,

optdef, machine, operatingConditions, engine)